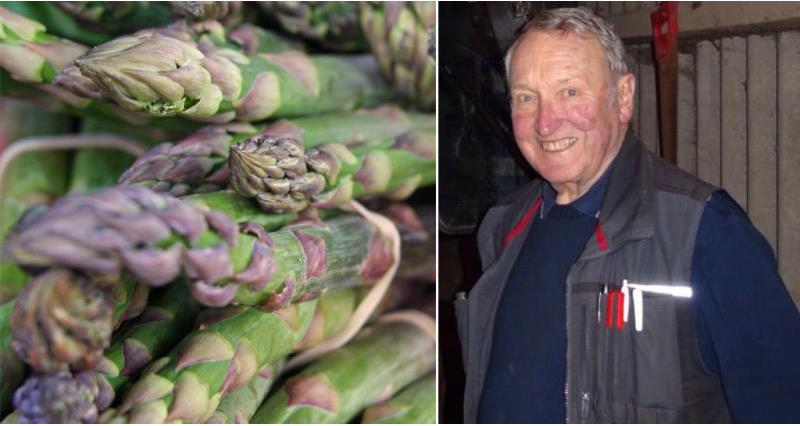

Dyas Farms on the Isle of Thanet, Kent, encompasses 25 acres of crops, from combinable crops such as wheat, peas and linseed, to vegetables including onions, cauliflower, cabbage and, most importantly, asparagus.

“We first tried growing asparagus in the family kitchen garden and discovered, to our delight, that it not only seemed to thrive, but our particular soil type seemed to impart it with a fantastic intense flavour,” Peter says. “So, in the spring of 2005, we hand-planted seven acres of asparagus, and our first harvest was in 2007.”

Peter grows varieties called Gijnlim and Backlim, and has planted a later variety called Portlim – which are all Dutch-grown crowns. “Crowns are planted in early April when ground conditions are suitable," he explains. "Asparagus likes sandy soil, ideally. Ours is what’s known as ‘brick earth’, which is slightly heavier than ideal, but it does impart a better flavour than asparagus grown on sand. Asparagus likes warm weather with an equable night temperature.”

Harvesting is totally dependent on the weather temperature. Peter says the ideal time is from 1 April till 21-24 June, but no later, otherwise it affects the growth of fern on which the next year’s crop is dependent.

Weather is one of the biggest issues for the asparagus industry. “There’s a very good market for English asparagus, but if it arrives late, the supermarkets often buy from South America," Peter says. “Then, when the English asparagus is ready, they’re overstocked and end up selling our English asparagus at a lower price, which obviously affects the trade going forward.”

Dyas Farms uses electric asparagus buggies to harvest. Farm workers drive the buggies along the field, leaning out to cut the asparagus spears by hand with a special serrated knife. When cut, the asparagus is put into a cold store as quickly as possible to get rid of field heat. Each cold store has special misting equipment to prevent the asparagus dehydrating.

“It’s quickly brought in from the fields to our on-site cutting room and shop, where it’s carefully washed, graded by computer-controlled laser, and prepared for sale," Peter says. "By preparing and chilling our asparagus quickly, its quality and freshness is assured.”